[{“部分”:“新闻”,“文本”:“2023年迪拜国际皮革展|服务全球皮革和时尚行业|现在注册”,“LandingURL”:“https://adsclick.fibre2fashion.com/app/clk/?q=07lrR3Iex48lWl + gszBH7x8K0JeON8Mq3yrDChrjVeCIoJ2O4CfXkfu5xC5ZdJ8ko8e7UpuSahzjDcuMbXOk5McSqLNLpE4pBe0klcKjisScAr + SosTy157ROAeW + P0qDbIkx7kkEyZaEjwc3sgj8mcZ88KHw6/1LK1EsIoQ8suBLP4fi / tVWEvn5TmrvZ4b7OjuE9 + Xj4DifS6Hb5XAp9W49W9GSB6h0bbL6Yze + ijfXxMbmk / kzmGH1MeqyJz + 8 yourmpauofe8snm8uzx7fbow + IkR + F7u + S2LgaHfUCF3Sk6vX2vUkFADuRnZZ6DTp8T0KHx18gF4C0g2tJz0D7vhJzlpijeUN37y49kCGXnRQ3pHXDY / rmH2fRWed5kwJLgqwzTxpzyqd3dw9NVExYtw7Ldhk0A1j j5id + KZNxKwJFF7Ey8xgdO7kcFxHWn9etFCgdW5z0uae9LespmTbg70n0BUWfH4Vw5SE2qsc3jemnLf2iFFs4a+GZkcAodOOZaiEA4Guib+wGQ1eX3yayq2zmfDDaB94ENalJE8uCweMirg7rmMALfme+GrtQ", "Order": "1", "Type": null, "ImpressionURL": "https://static.fibre2fashion.com/spacer.gif"}]

德国巴斯夫推出了使用Elastollan、BASF's热塑性聚氨酯(TPU)的骨科鞋垫。TPU被duro3D摊铺机用作灯丝,使用3D打印工艺生产单个鞋垫。在唯一的应用中,该材料的主要特点是其出色的减振和弹性。由TPU细丝制成的鞋底,使其具有完全和全面的可回收性。在大量使用的情况下,当用于运动鞋时,也是耐磨性使鞋底经久耐用,穿着舒适。即使温度波动,刀片也能保持其所需的性能。热塑性材料与3D打印(FDM)中不连续挤压的挑战完美匹配,使得在鞋底中绘制不同密度的宏观结构成为可能,而这反过来也有选择性地根据非常个性化的需求量身定制。该公司在一份新闻稿中表示,因此,填充物密度较低的柔软鞋底区域可以缓解疼痛,并顺畅地流向另一个区域,而另一个区域则可以坚定地支撑和稳定填充密度较高的脚部。德国巴斯夫推出了使用Elastollan(巴斯夫的热塑性聚氨酯(TPU))的骨科鞋垫。TPU被duro3D摊铺机用作灯丝,使用3D打印工艺生产单个鞋垫。在唯一的应用中,该材料的主要特点是其出色的减振和弹性。

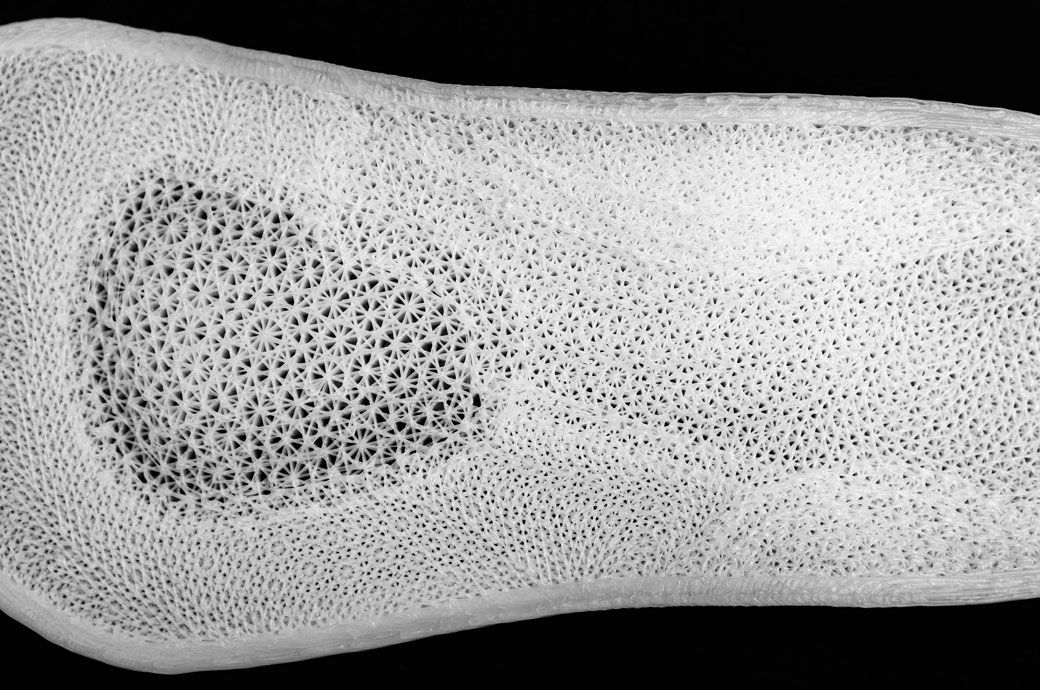

Usually, the Elastollan types of 85 Shore A (soft) and 95 Shore A (hard) are used in orthopaedic insoles to support the entire skeleton, but also in insoles for sports shoes, where a special load cushioning or support is desirable due to increased footwork. The open grid structure of the material also makes the sole breathable. Through the so-called smoothing, by the production of flowing, linear transitions between two hardness areas of the sole, unpleasant hard edges are completely avoided, the width of the transition area is customisable. This fully demonstrates the full application flexibility of Elastollan.

The production of shoe soles made of TPU filaments enables complete and comprehensive recyclability. In contrast to commercially available milled soles made of foam materials, the material can simply be mechanically shredded, re-extruded, and granulated after the use cycle. Used deposits are combined with the production surplus according to type and completely recycled by a recycler. By making the insoles to measure, material is massively saved. Only the final required material is used. As a result, there is almost no surplus in production. A production of the soles with thermoplastic polyurethane based on renewable raw materials is also conceivable in principle.

Fibre2Fashion News Desk (GK)

">